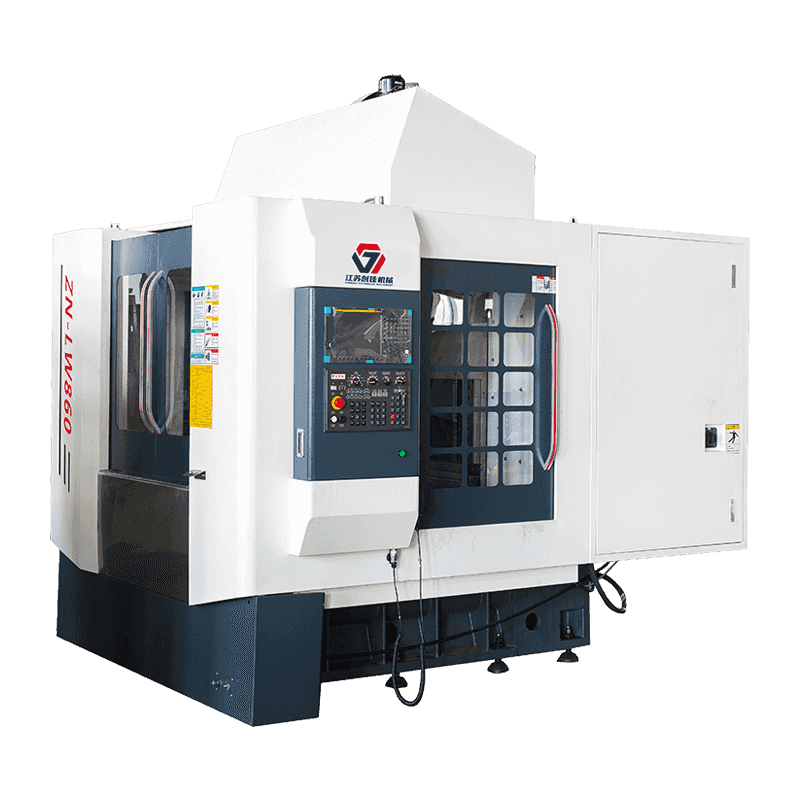

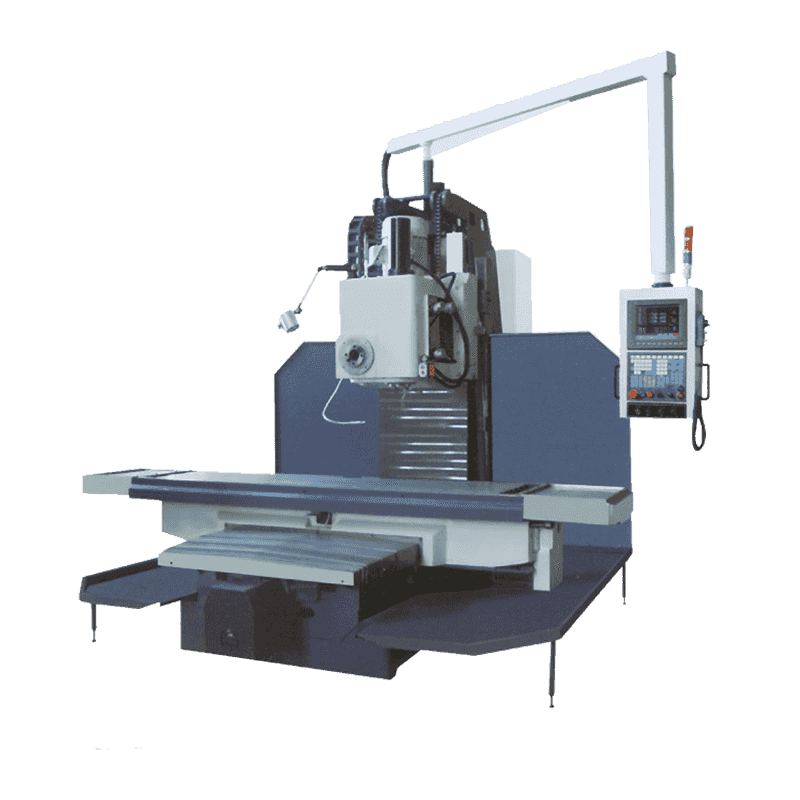

This series of machining center is fixed in A-shape single column, mobile structure of workbench, high rigidity of basic parts, lightweight of moving parts, fully fit the needs of users. The standard ...

Full process production mode, accurately control every link

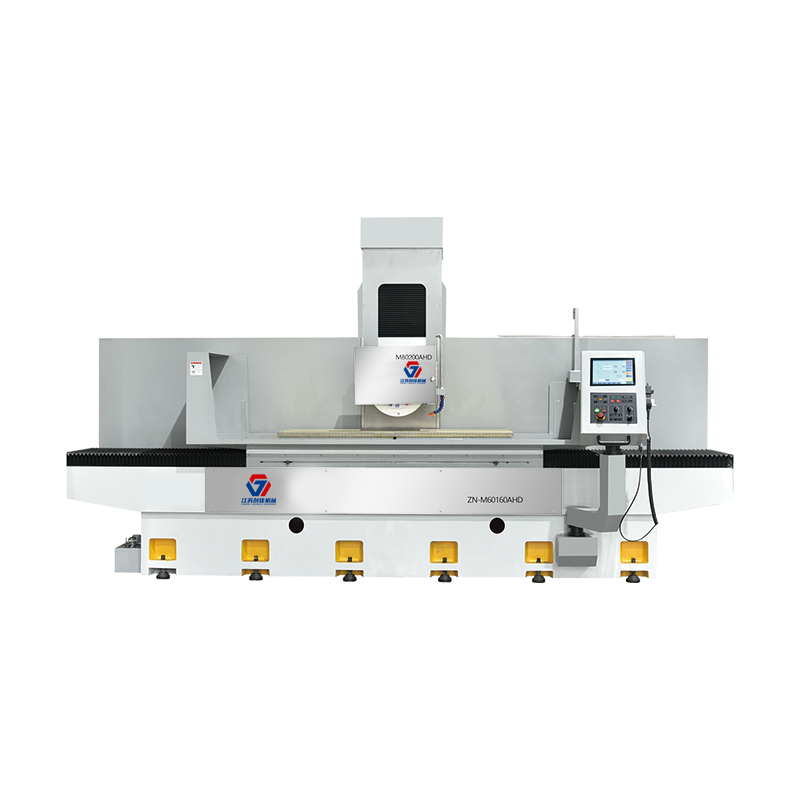

China CNC surface grinding machine manufacturers and custom small surface grinding machine suppliers

. The group boasts its own core technology and manufacturing capabilities. Since its inception in 2000, starting with CNC grinding machines, it has gradually developed and manufactured processing equipment such as CNC vertical machining centers, high-precision gantry machining centers, horizontal machining centers, CNC vertical and horizontal milling machines, CNC inclined bed lathes, turn-mill compound centers, CNC precision grinding machines, casting product production lines, and other specialized machine tools.-

0

founded in 2000

-

0+

technical personnel

-

0+

patents

- ZN-V850 Vertical Machining Center

- ZN-L1165 Vertical Machining Center

- ZN-L1580 Vertical Machining Center

- ZN-T6 Tapping Center

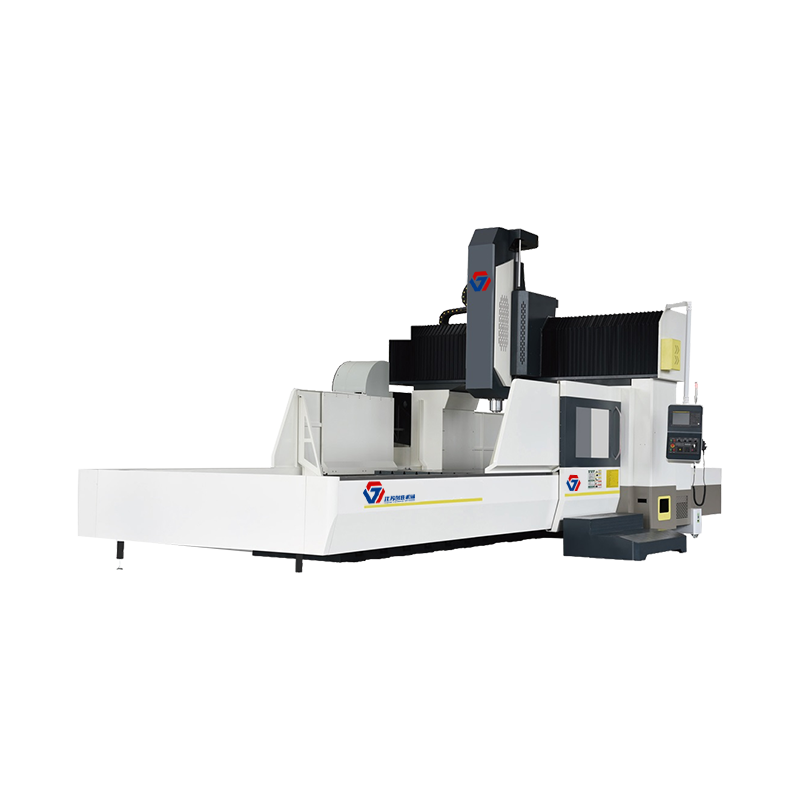

- LM3023 Gantry Machining Center

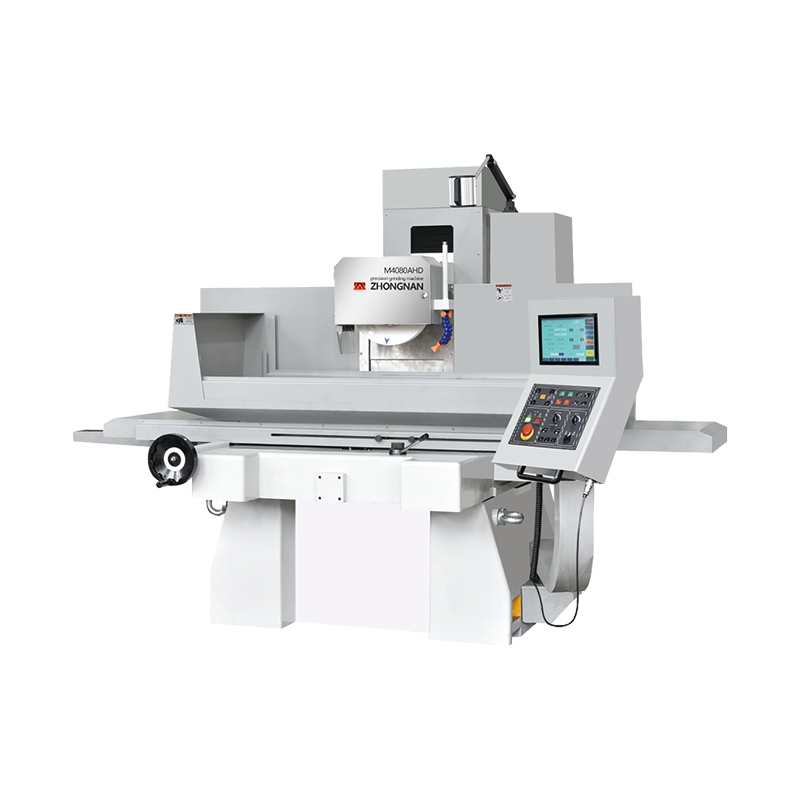

- M4080 Precision Surface Grinding Machine

-

Electronics Industry

Electronics Industry

-

Medical Industry

Medical Industry

-

Aerospace Industry

Aerospace Industry

-

Agricultural Machinery Industry

Agricultural Machinery Industry

-

Automotive Industry

Automotive Industry

-

01

Production Environment

From design, casting to commissioning and delivery Full process production mode,accurately control every link.

-

02

R& D and Manufacturing

With a technical innovation team led by the general manager, there are more than 380 employees, 30 senior engineers and 20 R & D designers.

-

03

Quality Inspection

Has its own technology research and development center and research institute, and invested heavily to build advanced CAD design center. Advanced manufacturing equipment and measuring instruments.

-

04

Complete Production Line

We have a complete production line, standard at home and abroad advanced level, for the company's products quickly respond to market demand to provide strong support, now the production capacity of more than 3000 sets.

-

How does a CNC Tapping Center ensure consistent thread depth and pitch across large production batches?

High-Precision Servo SynchronizationThe CNC Tapping Center relies on high-resolution servo motors that precisely control the movement of the machine...

-

How does the Vertical Horizontal CNC Milling Machine handle simultaneous multi-axis operations for complex part geometries?

Advanced Multi-Axis CNC Control Systems The ability of Vertical Horizontal CNC Milling Machine to perform simultaneous multi-axis operations begins wi...

-

What are the key operational advantages of using a CNC Power Milling Machine compared to manual milling machines?

Enhanced Precision and AccuracyCNC power milling machines provide unparalleled precision and dimensional accuracy, far exceeding what is achievable wi...

-

How does the CNC Gantry Machining Center ensure high precision and accuracy in complex machining operations for large parts?

Rigidity of the Gantry Structure The rigid gantry structure is a fundamental feature of the CNC Gantry Machining Center that ensures the accuracy of l...

en

en 简体中文

简体中文 русский

русский Español

Español