Applications in Various Industries

The

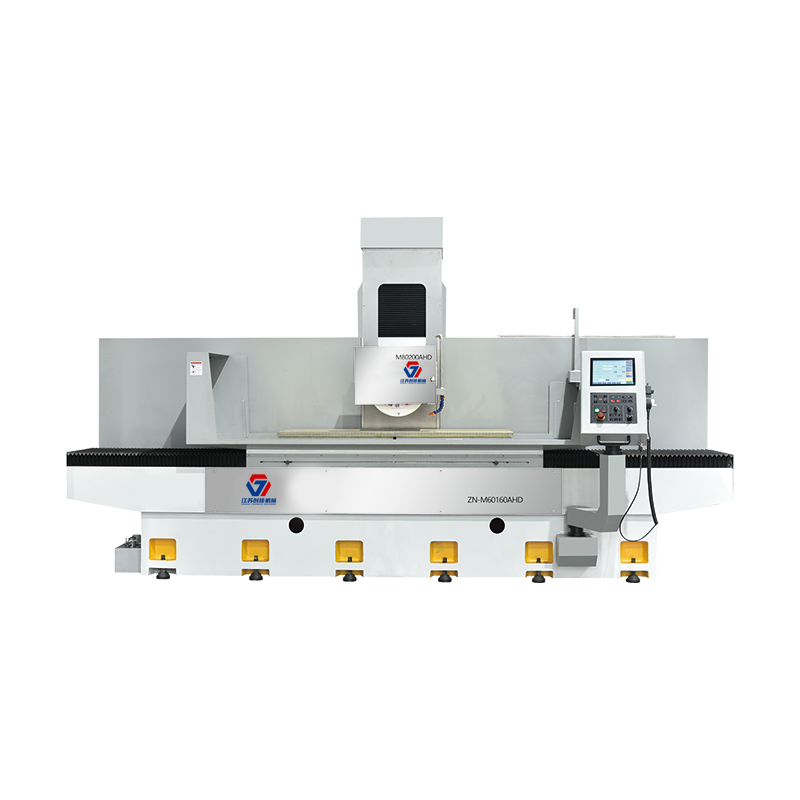

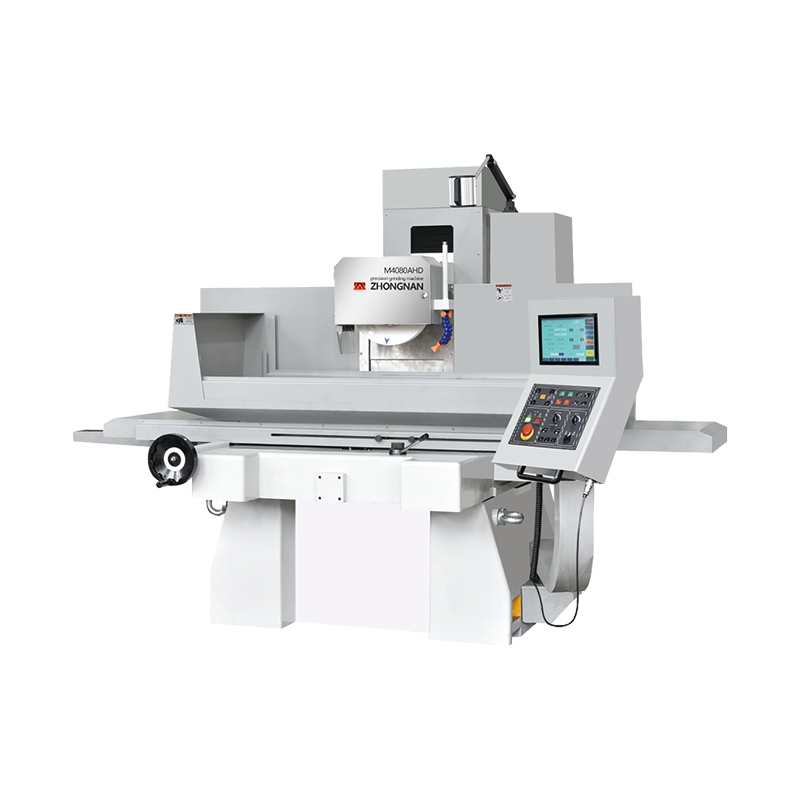

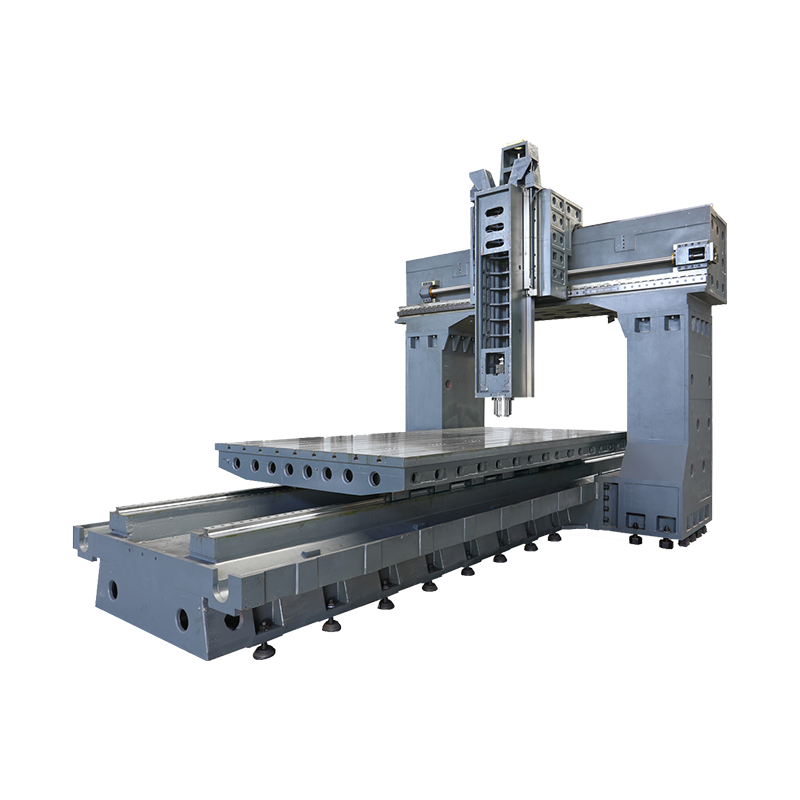

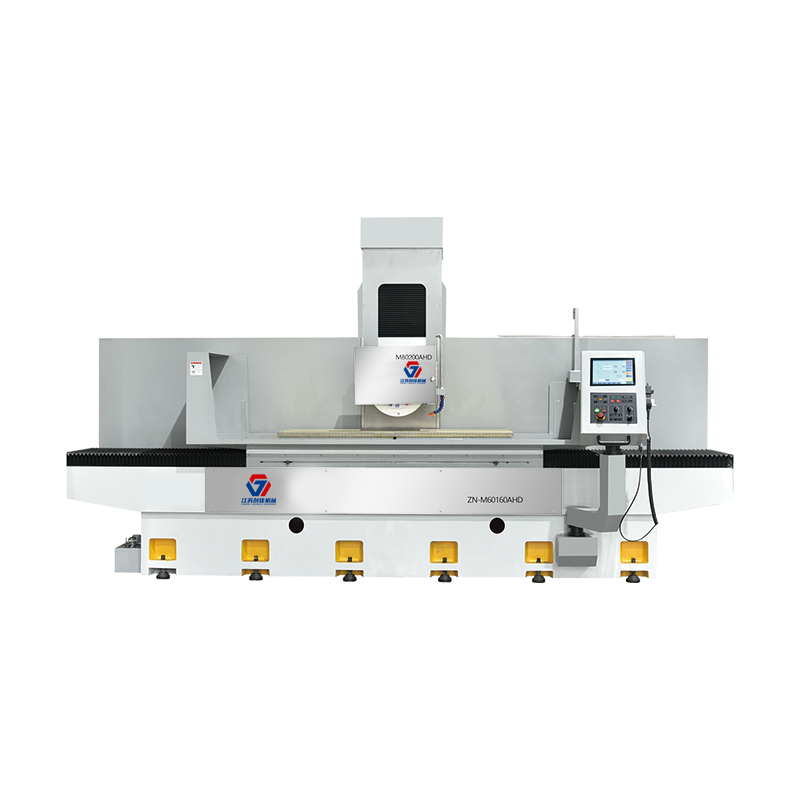

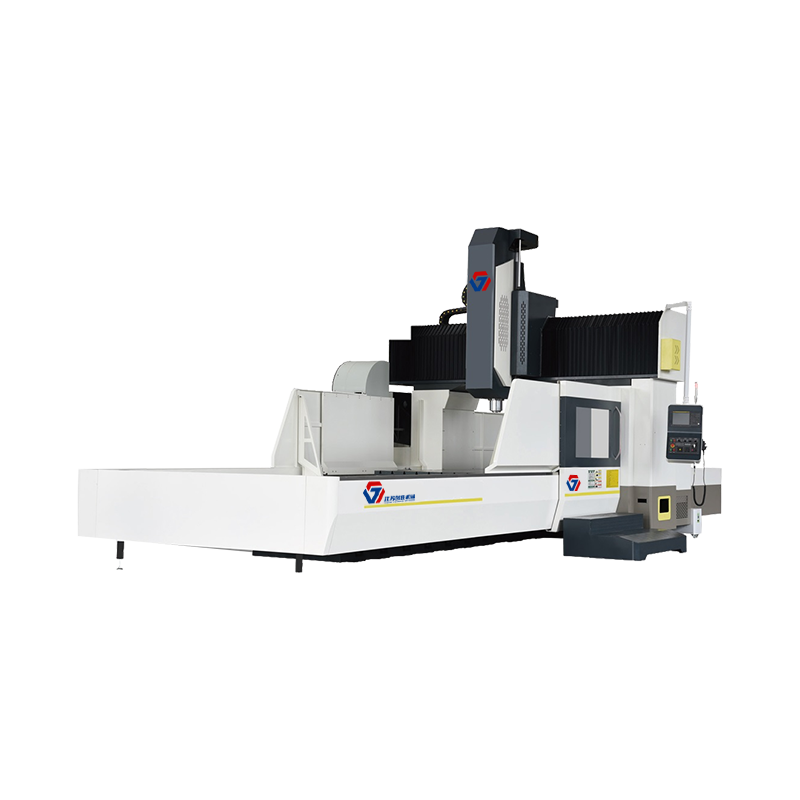

LM3023 Fully Enclosed Gantry Machining Center is designed to address the complex demands of various industrial sectors, showcasing its versatility and precision. As a flagship product of Jiangsu Chuangjia Machinery Co., Ltd., the LM3023 has become indispensable in numerous applications, reflecting the company's commitment to quality and innovation.

In the aerospace sector, precision and reliability are paramount. The LM3023’s capabilities enable it to produce intricate components that meet stringent industry standards. Its high-speed machining and accuracy facilitate the production of parts such as turbine blades, structural components, and housings for engines. The fully enclosed design minimizes contamination and enhances safety, making it ideal for sensitive operations that require strict adherence to cleanliness and precision. Furthermore, the machining center's ability to handle various materials, including lightweight composites and high-strength alloys, allows manufacturers to optimize performance while ensuring the structural integrity of aerospace components.

The automotive industry has witnessed a significant transformation with the advent of CNC machining technologies. The LM3023 plays a crucial role in producing high-precision components essential for vehicle assembly, such as engine blocks, transmission housings, and chassis parts. With Jiangsu Chuangjia Machinery Co., Ltd.'s focus on advanced manufacturing techniques, the LM3023 is equipped to handle large volumes without compromising quality. Its high machining speed and accuracy not only enhance productivity but also reduce material waste, contributing to more sustainable manufacturing practices. Additionally, the integration of automation and robotics with the LM3023 allows for streamlined workflows, facilitating just-in-time production that is vital in today’s fast-paced automotive environment.

As the world shifts towards sustainable energy solutions, the LM3023 has found applications in the new energy sector, particularly in the production of components for renewable energy systems such as wind turbines and solar panels. The machining center's ability to handle large parts and its precision makes it suitable for manufacturing key components like turbine blades and solar module frames. Jiangsu Chuangjia Machinery Co., Ltd. leverages its technical expertise to ensure that the LM3023 meets the rigorous standards required in the new energy industry, supporting the global transition towards cleaner energy sources.

In mold manufacturing, where precision and surface finish are critical, the LM3023 shines as an ideal solution. The machining center enables the production of molds for various applications, including injection molding and die casting. Its high precision allows for the creation of complex geometries that are essential for producing intricate parts in industries such as consumer electronics, packaging, and automotive components. Jiangsu Chuangjia Machinery Co., Ltd.'s dedication to quality ensures that the molds produced using the LM3023 deliver excellent performance, reducing the cycle time and improving the overall efficiency of the manufacturing process.

The medical device industry demands high precision and stringent regulatory compliance, making the LM3023 a vital tool in this field. With its ability to work with a variety of materials, including biocompatible plastics and metals, the machining center can produce components for surgical instruments, diagnostic devices, and prosthetics. The fully enclosed design enhances cleanliness, which is crucial in preventing contamination during the manufacturing process. Moreover, Jiangsu Chuangjia Machinery Co., Ltd. maintains strict quality control processes to ensure that every component produced meets the necessary safety and performance standards.

In the electronics sector, the demand for precision components continues to grow, driven by the advancement of technology and miniaturization of devices. The LM3023's capabilities make it ideal for machining intricate parts for various electronic applications, such as circuit boards, casings, and connectors. The machining center's high-speed capabilities allow for efficient production, meeting the rapid turnaround times required in this fast-paced industry. Additionally, Jiangsu Chuangjia Machinery Co., Ltd. utilizes advanced tooling and machining strategies to ensure optimal performance and surface finish, which are critical for electronic components.

The rail and heavy machinery industries rely on robust and durable components that can withstand extreme conditions. The LM3023 is capable of producing high-precision parts such as axles, frames, and undercarriage components, ensuring that they meet the rigorous demands of these applications. Jiangsu Chuangjia Machinery Co., Ltd.'s expertise in machining heavy-duty components ensures that the LM3023 can deliver high-quality parts that enhance the reliability and performance of rail and heavy machinery.

en

en 简体中文

简体中文 русский

русский Español

Español