Jiangsu Chuangjia Machinery Co., LTD.

Jiangsu Chuangjia Machinery Co., Ltd. belongs to Nantong Zhongnan Intelligent Technology Co., Ltd. The group company owns Zhongnan CNC Marine Tool, Xinsheng CNC technology , and other subsidiaries.

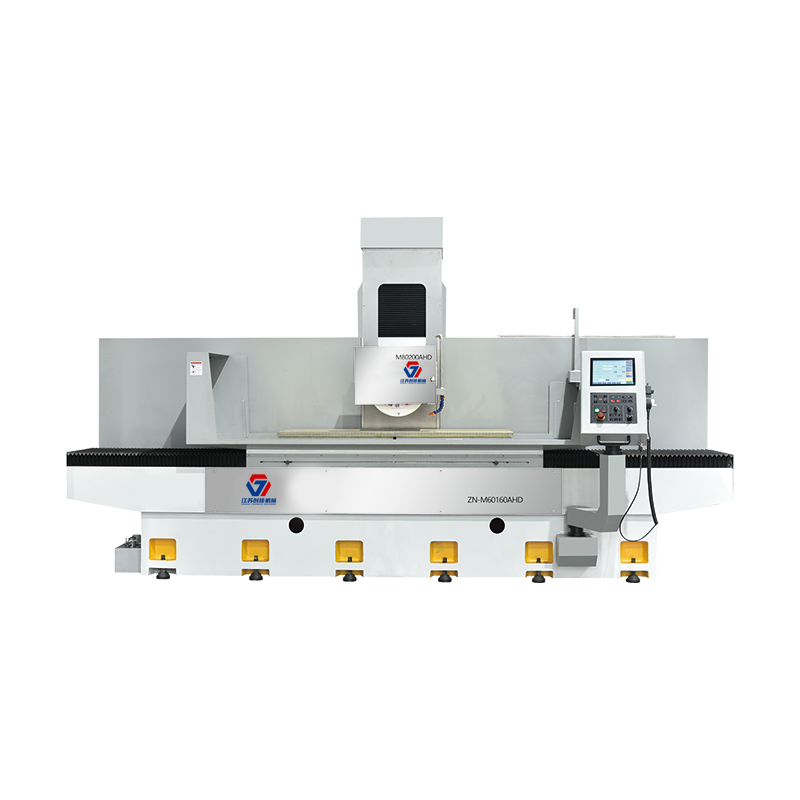

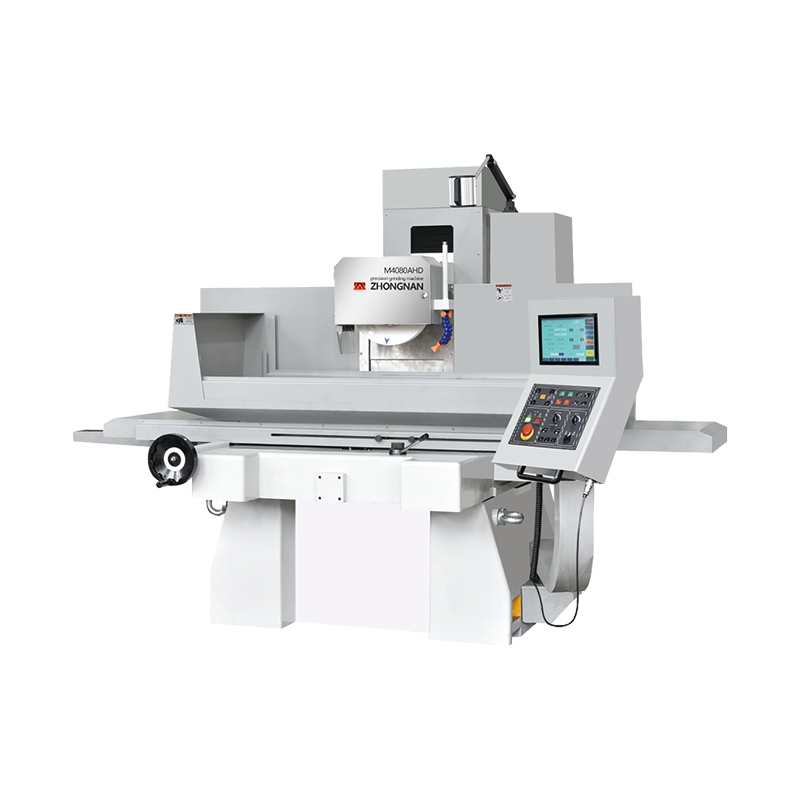

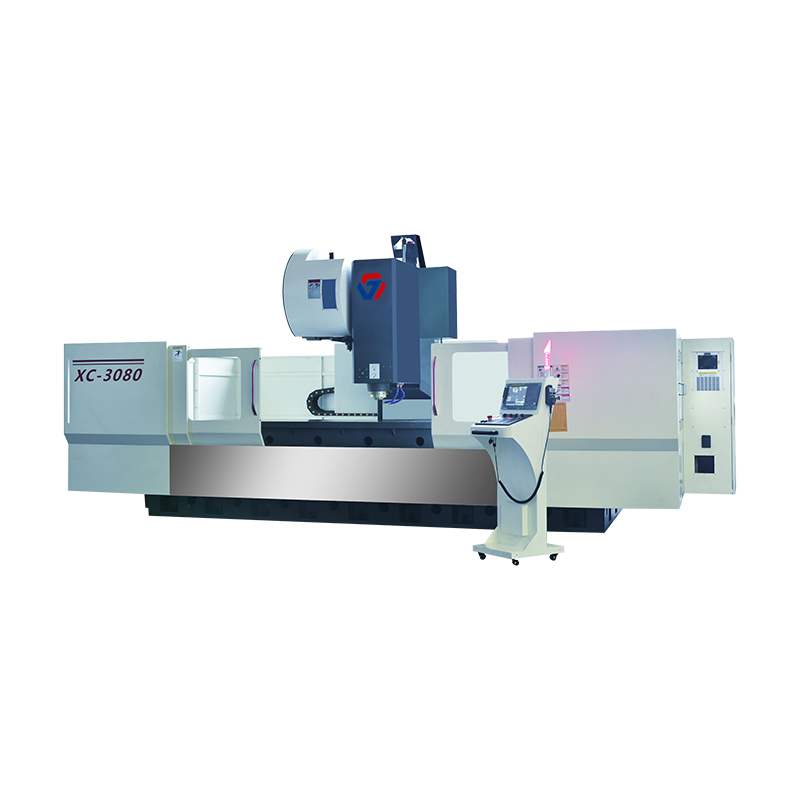

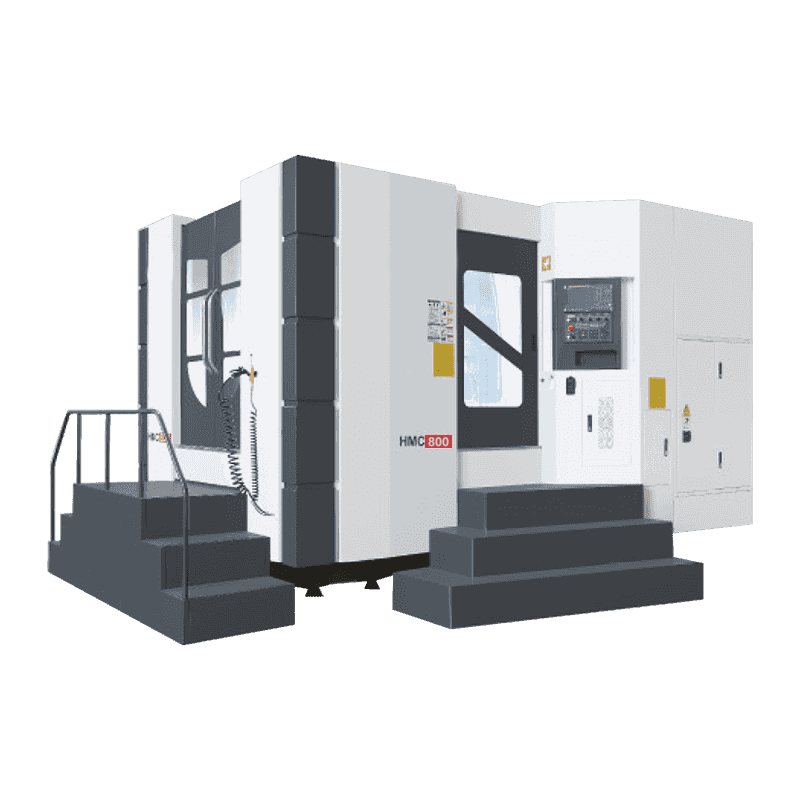

Since its establishment in 2000, started with producing surface grinding machines, and gradually developed into high-end CNC machining center and manufacturing with production line of CNC vertical machining center,high precision gantry machining center, horizontal machining center, CNC vertical horizontal milling machines, turning and milling complex center, CNC precision grinding machines, casting product production line and other machine tool products line. As

China ZN-T20 Automatic tool changing tapping center Suppliers and

ZN-T20 Tapping Center Factory. The group company has a complete production line, has its own professional foundry, sheet metal processing workshop, painting workshop, etc. It is a professional manufacturer with desirable products and strong technical strength in the domestic metal cutting industry chain. The company's products are widely used in sapphire, automobile, new energy, mold manufacturing and other industrial fields.

Jiangsu Chuangjia has a production park covers 100,000 square meters.There are more than 380 employees,30 senior engines, and 20 R&D engineers. The group company has its own technology research and development center - grinding machine Research Institute, and has built the domestic advanced CAD design office,obtained a number of independent invention patents. Production capacity covers the entire production chain of casting manufacturing, machining,painting,assembly,commissioning,inspection,etc.

Our mission: "exquisite technology, adhering to professional". Our service concept is "innovation, creation, integrity, quality". Sincerely look forward to win-win cooperation with you and create a good business together.

en

en 简体中文

简体中文 русский

русский Español

Español